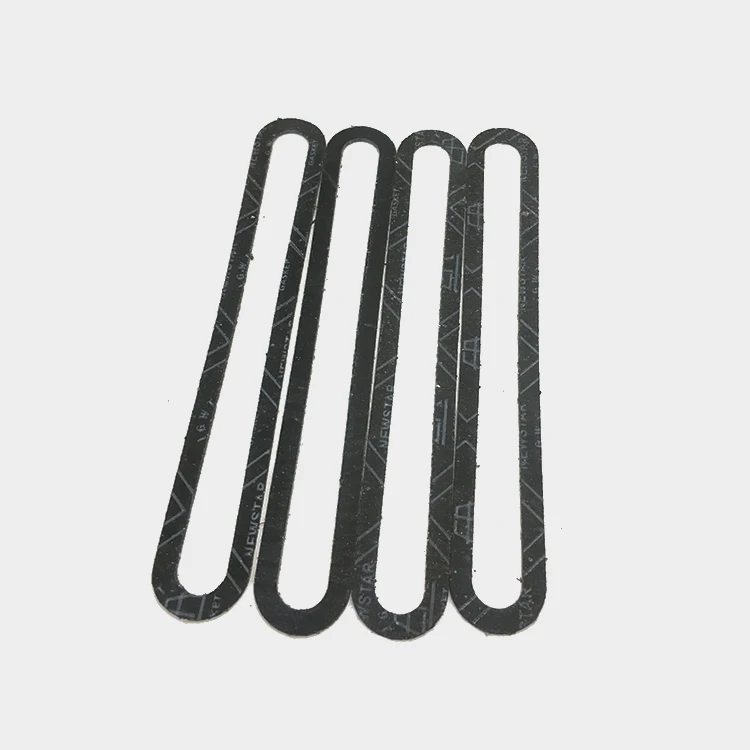

A0 95mm*30mm*17mm Reflex level gauge glass water level gauge for boiler

A0 95mm*30mm*17mm Reflex level gauge glass water level gauge for boiler

Reflex glasses is made from tempered borosilicate glass, it can be used with all media at service conditions up to 4MPa and temperature up to 430 °C.

The side facing the medium chamber is provided with molded grooves set at 90°angles. The moulding process increases the resistance of the glass grooves to wear; the skin which the glass attains during moulding gives it maximum smoothness and hardness.This makes it extremely resistant to the attack of boiler water.

It is used on level gauge of boiler for water position. It is also named: Reflex Gauge Glass, Sight glass, Reflex Glasses, Reflex sight glass, Spares For level Gauge.

Level Gauge Glass Physical Property

Testing Item Standard Rules

1. Appearance

1) Air bubble:

Diameter≤0.5mm,in the 10mm x 10mm area the quantity must be ≤3.

Diameter from 0.5mm to 1.5mm dispersive air bubble,there is less 2 on the sight plane and less 5 on the No-sight plane. Their distance must be 40mm.

The air bubble of Diameter from 1.5mm to 2mm ≤3 on the No-sight plane. Their distance must 40mm.

On the sight plane, The distance to the side in 7.5mm,the air bubble of the diameter1mm mustnt be more 2.

2) The glass dont allow slag and scrap iron,etc. impurity.

3) Stripe : dont allow have palpable filaceous and pectinate stripe on the sight plane.

4) Cockle: In the side face,dont allow have the cockle of depth 1mm.

5) Crack: dont allow have crack.

6) Scrape: On the sight plane and in the 7.5mm to edge,the scrape of less than 10mm dont allow more 2 strips.

7) The sight plane must be polishing,and sealing side must be rubbing and polishing.

2. Colour and Lustre

It should be no color and transparent,and with its self tine green is allowed.

3. Water-resistance

Cooked in the water for 5 hours,then weigh up ,then titration with 25ml 0~31 ug/g

4. Alkali-resistance

Cooked in the 0.5N NaoH for 3 hours,then Weigh up,weightlessness should be ≤75 mg/dm2

5. Temperature-resistance impacts capability

Put it into electric cooker,keep for 7min under the temperature of 260±1,then,put into the water of 20±1,it should not crack

6. Bend-resistance

≥80 MPa

1. Appearance

1) Air bubble:

Diameter≤0.5mm,in the 10mm x 10mm area the quantity must be ≤3.

Diameter from 0.5mm to 1.5mm dispersive air bubble,there is less 2 on the sight plane and less 5 on the No-sight plane. Their distance must be 40mm.

The air bubble of Diameter from 1.5mm to 2mm ≤3 on the No-sight plane. Their distance must 40mm.

On the sight plane, The distance to the side in 7.5mm,the air bubble of the diameter1mm mustnt be more 2.

2) The glass dont allow slag and scrap iron,etc. impurity.

3) Stripe : dont allow have palpable filaceous and pectinate stripe on the sight plane.

4) Cockle: In the side face,dont allow have the cockle of depth 1mm.

5) Crack: dont allow have crack.

6) Scrape: On the sight plane and in the 7.5mm to edge,the scrape of less than 10mm dont allow more 2 strips.

7) The sight plane must be polishing,and sealing side must be rubbing and polishing.

2. Colour and Lustre

It should be no color and transparent,and with its self tine green is allowed.

3. Water-resistance

Cooked in the water for 5 hours,then weigh up ,then titration with 25ml 0~31 ug/g

4. Alkali-resistance

Cooked in the 0.5N NaoH for 3 hours,then Weigh up,weightlessness should be ≤75 mg/dm2

5. Temperature-resistance impacts capability

Put it into electric cooker,keep for 7min under the temperature of 260±1,then,put into the water of 20±1,it should not crack

6. Bend-resistance

≥80 MPa

High quality Water level indicator with boiler level gauge glass

1. Providing technical consultation.

2. Special packaging according to request.

3. Providing related qualification documents.

4. Accepting customer's audit on site.

5. Providing shuttle bus service when visiting our factories.

6. Solving the quality matter on production line, providing technical inspection.

7. Solving customer's complaints in time and making advancement.

1. Providing technical consultation.

2. Special packaging according to request.

3. Providing related qualification documents.

4. Accepting customer's audit on site.

5. Providing shuttle bus service when visiting our factories.

6. Solving the quality matter on production line, providing technical inspection.

7. Solving customer's complaints in time and making advancement.

Comments

Post a Comment