What are the Precautions for Level Gauge?

Precautions

The correct selection of Level Gauge can ensure the better use of the level gauge. What kind of liquid level meter should be selected according to the physical and chemical properties of the measured fluid medium? The diameter, flow range, lining material, electrode material and output current of the liquid level meter can be adapted to the properties of the measured fluid And flow measurement requirements.

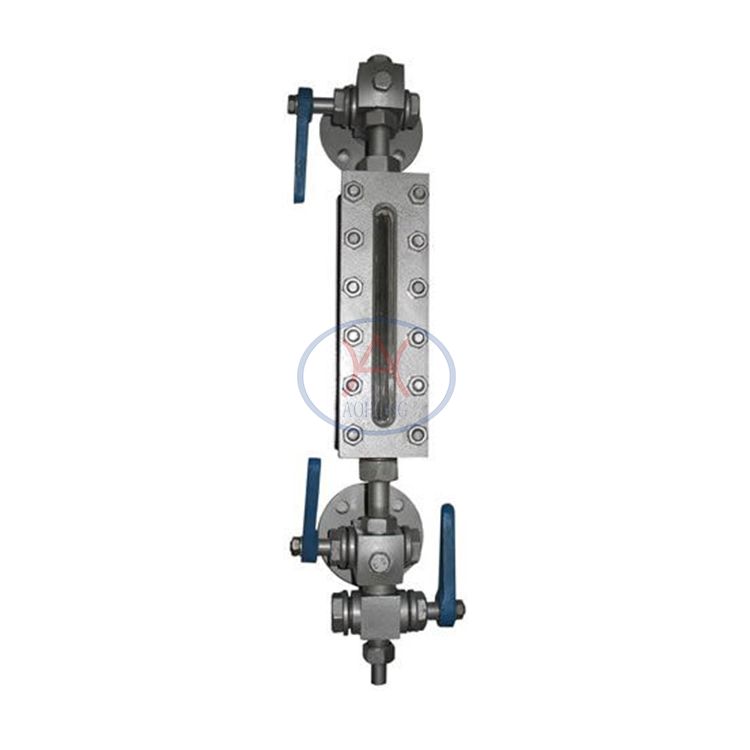

Reflex Gauge Glass

1. Precision function check

Accuracy level and function According to the measurement requirements and application occasions, select the instrument accuracy level to achieve economical and cost-effective. For example, for trade settlement, product transfer and energy measurement, you should choose a higher accuracy level, such as 1.0, 0.5, or higher; for process control, choose different accuracy levels according to control requirements; some only It is the occasion to check the process flow without precise control and measurement. You can choose the lower accuracy level, such as 1.5, 2.5, or even 4.0. At this time, you can choose a low-cost plug-in level gauge.

2. Measurable medium

Measuring medium flow rate, instrument range and caliber When measuring general medium, the full-scale flow of the liquid level gauge can be selected within the range of measuring medium flow rate 0.5-12m/s, and the range is relatively wide. The specifications (caliber) of the selected instrument are not necessarily the same as the process pipeline. It should be determined according to whether the measurement flow range is within the flow rate range, that is, when the pipeline flow rate is too low to meet the requirements of the flow meter or the measurement accuracy cannot be guaranteed at this flow rate, Need to reduce the diameter of the instrument, so as to increase the flow velocity in the tube, and get satisfactory measurement results.

Troubleshooting

Routine inspection of liquid level gauge and troubleshooting method, suitable for magnetic flap liquid level gauge, two-color quartz tube liquid level gauge, glass tube liquid level gauge, etc.

1. First check whether the power supply is connected correctly. If you find that the connection is incorrect, you should modify it according to the operation manual.

2. Use a three-voltmeter to measure the voltage between +24V and O/P. The voltage should be between 13V and 36V. If the voltage is abnormal, check whether the circuit or related equipment is abnormal.

3. Item 2 should be confirmed to be normal first, and then connect a milliampere meter in the 4~20MA circuit to check whether the current is normal. If the current value is abnormal, replace it with a new product or contact customer service staff.

4. Check the voltage between IN and COM with a voltmeter. The normal voltage should be about 2.5V. If the voltage is too low, the EXC wire should be removed. If the voltage returns to normal, it means that the magnetic yellow module is abnormal. If the power is still low It means the signal converter is damaged. If you find the above phenomenon, you should replace the signal converter according to the actual situation or contact customer service personnel.

The float drops to the bottom and the flag board does not return to zero. The flag board cannot keep up with the speed of the float falling. A throttle device should be installed to slow down the liquid level.

Our company also has Reflex Gauge Glass for sale, please contact us.

Comments

Post a Comment